Little Tree Bali - Green Building Centre

telpon

Customer Service

+62 (0) 81139605497

Jika ada kebutuhan khusus, silakan kontak staf kami langsung.

toserba

Sekarang buka dari hari Senin sampai hari Sabtu :

8:00-17:00

KATEGORI PRODUK

Aircond Water Heater

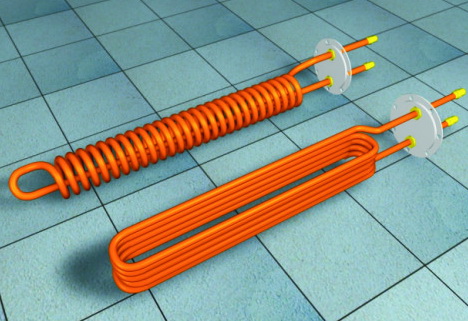

The Heat Exchanger Unit captures waste heat discharged produced in an Air Conditioning, Heat Pump or Generator system, and transfers that heat into a water heater tank, thereby creating low cost hot water for domestic and commercial use. Not only does the Heat Exchanger Unit substantially reduce the amount of energy required to provide hot water, but it also improves the thermal efficiency of the equipment connected to it while it is operating.

- 230 volt wiring for easy connection to compressor contactor

- Factory wired and preset controls

- Fully automatic operation

- High-Efficiency All-Copper vented Double-Wall Heat Exchanger

- Water lubricated low wattage Circulator

- Grounded electrical circuit.

- Sturdy Aluminum Cabinet with baked enamel finishes for outdoor or indoor use

- ARL listed Appliance, with UL approved components

- Freeze stat option available

- Water connection accessories available

The gas or liquid side of Heat Recovery Unit Heat Exchanger is installed in the hot gas line between the compressor and condenser; or between compressor and reversing valve, if installed on a Heat Pump System. For other heat source, such as generator, bypass and connect the oil suction pipe to the hot gas line. The water side of the Heat Exchanger is connected to the water heater tank to form a circulation loop. Power is drawn from the compressor contactor or outside source. Waste heat may be collected when the equipment operates, and the water circulating from the water heater tank is less than 140⁰F. A minimum gas or liquid temperature of 125⁰F is also required to allow Heat Recovery operation.

MOUNTING/LOCATION AQUEFIER Heat Recovery Units may be mounted indoors or outdoors. They must be mounted vertically, at a height above the top of the heat engine. While normally located outdoors, they can be located in any convenient place, such as the garage or laundry room..

CONTROLS All AQUEFIER models contain a water high limit control. It is factory set to 140°F. Models also contain a gas / oil low limit. It is factory set to 125°F. Freeze- protected models are equipped with a water low limit. It is factory set to 50°F, and is designed to operate when water temperatures of 40°F or less are detected, in order to provide water circulation independent of compressor operation, in the event of freezing ambient.

HEAT EXCHANGER AQUEFIER Heat Recovery Units contain a corrosion resistant all-copper double wall heat exchanger of counter flow twin tube design. Continuously vented along its entire length, the Heat Exchanger meets strict IAPMO safety criteria, and exceeds UL requirements.

CIRCULATOR PUMP AQUEFIER Heat Recovery Units contain a low wattage wet rotor in-line single stage circulator. Standard Models use a Taco 006 series circulator. This self-cooled pump is rated at 90 watts, 230 volts and .40 amps. It is designed for 125 psi working pressure and up to 220°F fluid temperature. The pump housing is bronze and the bearings are ceramic.

MODEL WEIGHT HR 06 Base Model 15 lbs HR06-F with Freeze-Stat HR06-V with hand valves & bleeds port HR06-PC with hand valves & PRV High Pressure (650psi test) Models wired 230V 1phase.

Liquid media Maximum allowable density 40 SAE

ACCESSORIES

PART NO. DESCRIPTION IK-5 Installation Kit L140 High water thermostat L50 Freeze control thermostat F125 Gas / Liquid low limit thermostat PV05 ½" Pressure relief valve T006 Taco 006 pump

THERMAL PERFORMANCE (ARI 470-2001)

Water side Gas / Liquid side Heat transfer EWT 95⁰F LWT 106⁰F Flow rate 2 gpm Entering 178⁰F Leaving 114⁰F Flow rate 730 lb/hr 11,145 Btuh Testing performed by APL, Miami, Fl Sept 2007

WARRANTY: AQUEFIER Heat Recovery Units offer a limited Parts Warranty as follows: Heat Exchanger- 1 year; Pump- 2 years; All other components - 1Year.

WATER LINE SIZING

Actual Size O.D

Nominal Size Length feet 1/2” 3/8” 40 5/8” 1/2” 100 3/4” 5.8” 150

HOT GAS / LIQUID LINE SIZING

Hot Gas / Liquid O.D

Nominal size Length feet 1/2" 3/8” 9 5/8” 1/2" 25 3/4" 5/8” 30

SIMILAR PRODUCTS

Lihat panduan kami Butuh info produk?

Kontak bagian penjualan kami Kenapa membuat

bangunan hijau? Kopi Kultur